|

Packaging Carbon Footprint Analysis

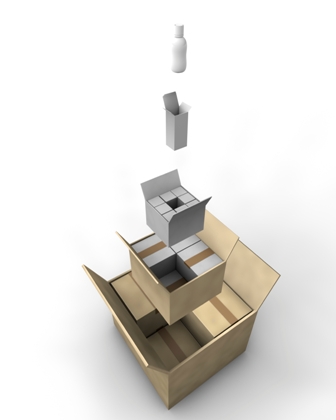

CleanMetrics now offers an integrated carbon footprint solution for the packaging industry. Using our standards-based life-cycle inventory database and our life-cycle assessment software tools, we can

provide reliable and high-quality life-cycle carbon footprint assessments for

all packaging products, materials and configurations.

Why Packaging Carbon Footprints?

Packaging is obviously

required to protect virtually all products in transit and storage until they

reach consumers. But most of us have routinely experienced over-packaged

products and the inefficient use of packaging materials is an area that is ripe

for optimization. Recycling rates have generally plateaued in most countries,

and in any case end-of-life recycling alone cannot move us toward sustainable

packaging. Packaging systems must be designed with care, using the least amount

of materials/energy, maximizing recycled content, and increasing the potential

for reuse. Understanding the full life-cycle of these systems is critical for

optimizing their environmental performance. A life-cycle carbon footprint

analysis of packaging systems -- for both consumer and industrial products -- is

a crucial analytical tool that can help advance the cause of sustainable

packaging. Packaging is obviously

required to protect virtually all products in transit and storage until they

reach consumers. But most of us have routinely experienced over-packaged

products and the inefficient use of packaging materials is an area that is ripe

for optimization. Recycling rates have generally plateaued in most countries,

and in any case end-of-life recycling alone cannot move us toward sustainable

packaging. Packaging systems must be designed with care, using the least amount

of materials/energy, maximizing recycled content, and increasing the potential

for reuse. Understanding the full life-cycle of these systems is critical for

optimizing their environmental performance. A life-cycle carbon footprint

analysis of packaging systems -- for both consumer and industrial products -- is

a crucial analytical tool that can help advance the cause of sustainable

packaging.

What are Packaging Carbon Footprints?

The carbon footprint of a packaging system is the total amount of carbon dioxide

carbon dioxide (CO2) and other greenhouse gases emitted over the life cycle

of that product or service, expressed as kilograms of CO2

equivalents. This includes all greenhouse gases generated in the manufacture of

the raw materials, fabrication of the packaging system, transport of materials

and finished systems, the use phase including refurbishment and reuse, and

end-of-life disposal. This carbon footprint is often included in the analysis of

the larger product system that uses the packaging, but it can also be seen as a

distinct environmental performance metric that can be calculated and optimized

separately.

Why CleanMetrics?

At CleanMetrics, we have worked on a broad range of commercial projects related

to packaging materials and systems, using life-cycle methods and focused on

carbon footprints. Our work has routinely included analyses of consumer product

packaging, bulk product containers/packages and secondary packaging

configurations that are produced using a range of virgin, recycled and

biodegradable materials -- including scenarios such as refurbishment, reuse,

recycling, and other end-of-life disposal. We understand that packaging systems

are more than just the materials used -- they are systems, with their own life-cycle

characteristics that must be modeled correctly. Our mission is to help your

business address the challenge of sustainable packaging with the best collection of

tools, data and expertise. At CleanMetrics, we have worked on a broad range of commercial projects related

to packaging materials and systems, using life-cycle methods and focused on

carbon footprints. Our work has routinely included analyses of consumer product

packaging, bulk product containers/packages and secondary packaging

configurations that are produced using a range of virgin, recycled and

biodegradable materials -- including scenarios such as refurbishment, reuse,

recycling, and other end-of-life disposal. We understand that packaging systems

are more than just the materials used -- they are systems, with their own life-cycle

characteristics that must be modeled correctly. Our mission is to help your

business address the challenge of sustainable packaging with the best collection of

tools, data and expertise.

Our life-cycle inventory database includes cradle-to-gate and/or unit process data for everything

needed to perform a complete life-cycle carbon

footprint analysis of packaging systems:

- Full range of virgin and recycled materials used in packaging systems --

including all types of plastics, glass, metals, fabrics, cardboard and

paper, as well as biodegradable fibers such as corn-based Ingeo and

sugarcane-based bagasse.

- Transportation, warehousing,

fuels, and electricity by grid regions.

- All common waste disposal methods -- such as landfill, incineration, compost,

reuse and recycling -- including energy recovery options.

The database is fully integrated with our life-cycle

assessment software tools and can be easily customized for your specific

application. We are continually adding data for more products/processes to the

database. We also offer a low-cost rapid research option to add data for

specific products or processes that you may need for your application.

Our Solutions

We offer a range of solutions depending on your needs and in-house expertise.

- For organizations with internal expertise in life-cycle assessment and product

carbon footprints, we can license our software products with integrated

life-cycle inventory database. We can also license our

database separately if

you have other means of performing the analyses.

- For organizations that are looking for a turn-key solution, we can use our

software tools, database and technical expertise to provide a complete

end-to-end solution

and deliver analytical results tailored for your specific business needs.

You can use our solutions in a variety of ways:

- Provide

consumer information such as product carbon labels or purchasing guides.

- Provide investor information such as corporate environmental reports.

- Identify hot spots in your supply and delivery chain, and make your

product/service more carbon efficient on a life-cycle basis.

© Copyright 2007-2011 by CleanMetrics Corp. All rights reserved.

CleanMetrics, CargoScope, CarbonScope, BuildingScope, CarbonScopeData,

FoodCarbonScope, Deep Carbon Footprinting, and MetaFlowScope are trademarks of CleanMetrics Corp. |

|